Pipe Threading Machine

United Machinery & Tools Corporation

Pipe Threading Machine

| TECHNICAL SPECIFICATION - Pillar type Pipe Threading Machine | ||||

| FEATURES & Model | 3/8" To 1 1/2" | 1/2" -2 1/2" | 1" to 4" & 2 1/2" to 6" | 4" to 8" |

| Saddle Movement | 10" to 12" | 7" | 10" | 10" |

| Spindle Speed Range | 125 to 180 | 32-54-85 | 28-48 | 28-48 |

| Number of Spindle Speed | 2 or 3 | 3 | 2 | 2 |

| Threading Capacity | 3/8" -1 1/2" | 1/2" -2 1/2" | 1" to 4" & 2 1/2" to 6" | 4" to 8" |

| Production per Hour | 60 to 80 | 45 to 80 | 35 to 40 | 35 to 40 |

| H.P. Required | 3 H.P.960 RPM | 7.5 H.P.960 RPM | 12.5 H.P.960 RPM | 12.5 H.P.960 RPM |

| Automatic Leading Cut off | NIL | NIL | Provided | Provided |

| Space Required | 24" x 65" | 42" x 65" | 60" x 96" | 60" x 96" |

| Weight (KG) | 550 | 990 | 1600 / 1900 | 2300 |

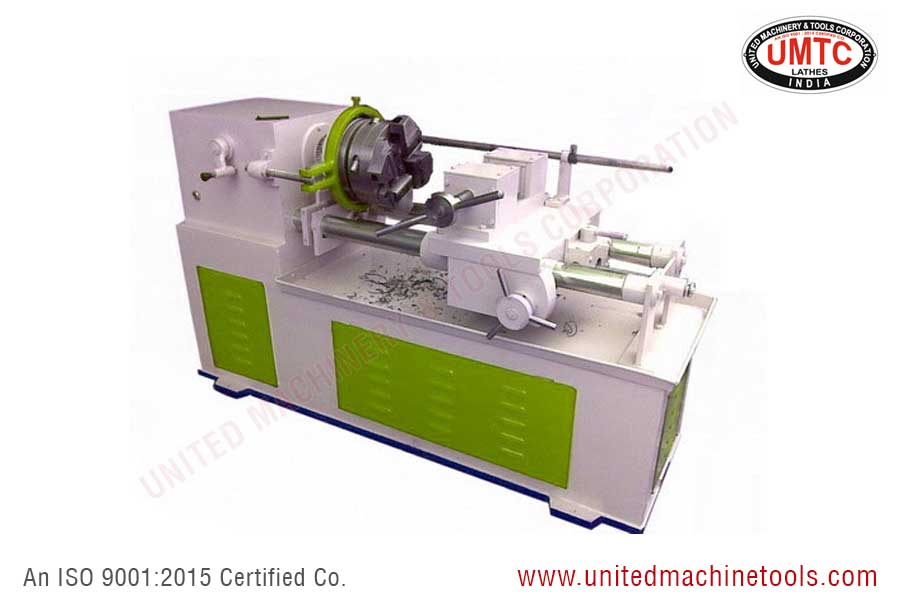

Bed Type Pipe & Bolt Threading Machine

| TECHNICAL SPECIFICATION -BED TYPE PIPE & BOLT THREADING MACHINE | ||

| Features & Model | 3/8" To 1.1/2" | 1/2" To 2 .1/2" |

| Saddle Movement | 10" to 12" | 7" |

| Spindle Speed Range | 60 to 90 | 32 to 54 to 85 |

| Number of Spindle Speed | 2 or 3 | 3 |

| Threading Capacity | 3/8" to 1. 1/2" | 1/2"to 2 .1/2" |

| Production per Hour | 60 to 80 | 45 to 80 |

| H.P. Required | 3 H.P. 960 RPM | 7.5 H.P. 960 RPM |

| Automatic Leading Cut off | As per demand | As per demand |

| Space Required | 24" x 65" | 42" x 65" |

A Pipe Threading Machine is a specialized machine tool used to cut threads on the ends of pipes so they can be joined together with fittings. This machine is commonly used in plumbing, gas, oil, and construction industries to ensure leak-proof and secure connections between pipe sections.

United Machinery & Tools Corporation is a leading high quality Pipe Threading Machines manufacturers and exporters in India, Punjab, Ludhiana, serving clients across the globe with precision engineering solutions. our company has built a strong reputation for delivering reliable, efficient, and technologically advanced Pipe Threading machinery tailored to meet the diverse needs of our clientele.

Our state-of-the-art Indian Pipe Threading Machine manufacturing facility is equipped with the latest machinery and tools, ensuring high precision and consistency. With a skilled workforce and dedicated R&D team, we continuously improve our technology and product offerings.

Note : In accordance with our continues improvements we reserve the right to change the design and specifications without any notice.For any Query, Contact Our Team