Slotting Machine

United Machinery & Tools Corporation

Slotting Machine / Heavy Duty Slotting Machines

Slotting Machine / Heavy Duty Slotting Machines

Slotting Machine / Heavy Duty Slotting Machines

Slotting Machine / Heavy Duty Slotting Machines

Slotting Machine / Heavy Duty Slotting Machines

Slotting Machine / Heavy Duty Slotting Machines

Slotting Machine / Heavy Duty Slotting Machines

Slotting Machine / Heavy Duty Slotting Machines

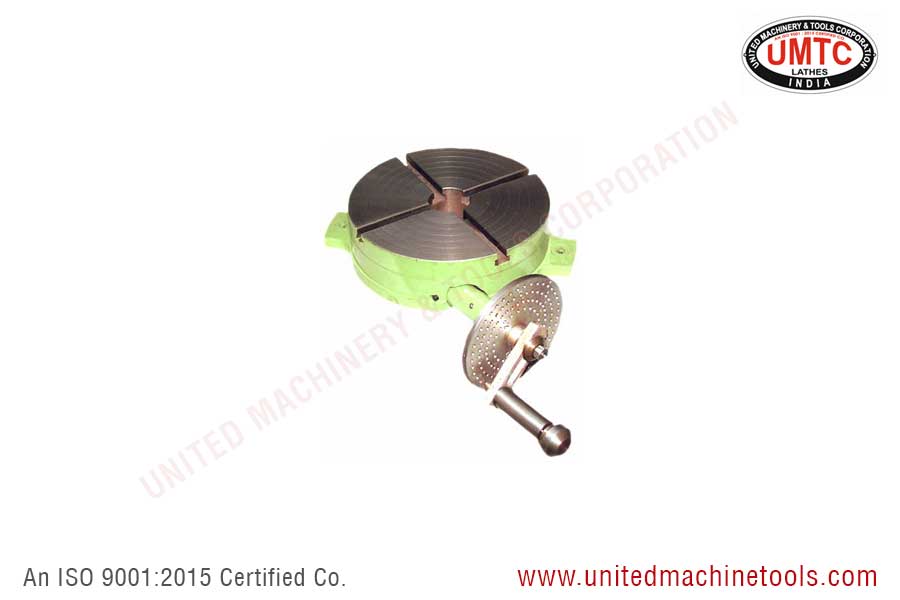

Rotary Table Suitable for Slotting Machine

| MODEL | 150 | 250 | 300 | 450 |

| Length of Stroke Maximum | 175 | 250 | 325 | 475 |

| Working Stroke | 150 | 225 | 300 | 450 |

| Ram Adjustment | 125 | 200 | 250 | 325 |

| Length of Ram Bearing | 500 | 550 | 625 | 875 |

| Throat Adjustment | 300 | 350 | 500 | 625 |

| Max. Dia. accommodated when M/C at centre | 500 | 750 | 850 | 1500 |

| Distance between table and head | 300 | 375 | 450 | 700 |

| Longitudinal feed ( Manual ) | 200 | 325 | 450 | 625 |

| Longitudinal feed ( Auto ) | 175 | 300 | 425 | 575 |

| Cross feed ( Manual ) | 225 | 250 | 400 | 550 |

| Cross feed ( Auto ) | 200 | 225 | 375 | 500 |

| Dimension of table | 275 | 375 | 600 | 900 |

| Number and Range of Speeds | 2( 30-50 ) | 3(30-60-90) | 3(25-40-65) | 6(10-15-25-35-50-70) |

| Motor recommended ( 960 RPM ) | 1.5 H.P. | 2 H.P. | 3 H.P. | 5 H.P. |

| Net weight | 850 Kg | 1750 Kg. | 1750 Kg. | 4000 Kg. |

| Gross weight | 975 Kg | 1900 Kg. | 1900 Kg. | 4500 Kg. |

| Packing Dimension | 1700x850x1200 | 2100x1400x900 | 2300x1500x1100 | 2500x2200x1600 |

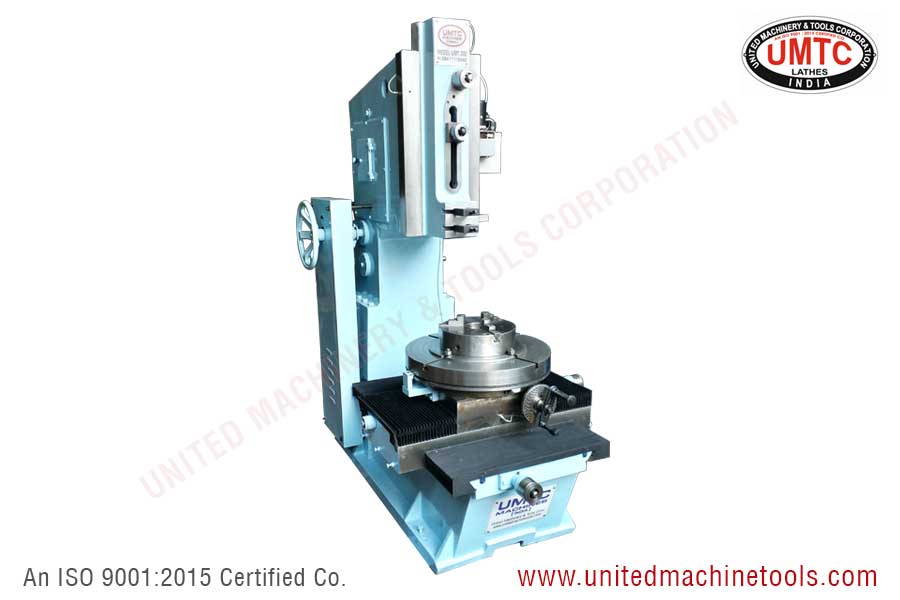

A slotting machine is a versatile machine tool used for shaping or cutting slots in a workpiece. It operates on the same principle as a shaper but has a vertical orientation. Here are the key components and working principles of a slotting machine:

CONSTRUCTION OF MACHINE :

COLUMN : The Column consists of two parts which are adequately ribbed & securely held together to form a rigid unit. The deep throat enables a wide variety of parts to be machined.

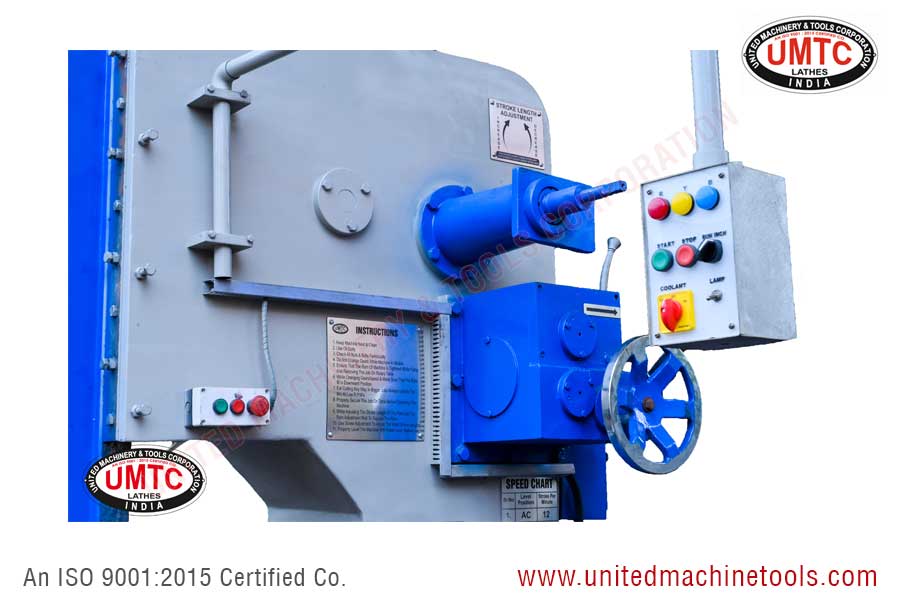

DRIVE : The Electric motor drives the clutch pulley and the gears fitted in the column. From there the power is transmitted to the ram by the means of link mechanism. The ram-movement is started by engaging clutch. The link mechanism allows for an accelerated ram-movement in return stroke Ram speed changes are effected by sliding gears controlled by shaft through gear box.

RAM : The ram is well ribbed and is quite strudy. An taper wedge is provided for smooth running. The ram can be tilted 5 degree on demand and swiveled 10 degree in case of 400 mm stroke.

TABLE : The table is circular and is provided with T-slots. It is divided on its circumference into 360 degrees. A tapered whole is provided in the center of the table for reception of the centering mandrel while machining circular slotting work. Direct Indexing is provided for accurately locating the various positions.

FEED : The feed mechanism mounted on the column through side gearbox. The feeds are infinitely within range of 0.2mm to 1.5mm for 150 mm, 250mm & 300 mm. In case of 450mm stroke 0.2mm to 2 mm per cycle. The feeds can be adjusted when machine is at the rest.

OUT STANDING FEATURES :

- High grade casting for wear resistance and rigidity.

- Single lever control for changing the speeds

- Centralized machine controls on operating side

- Steel gear sliding on multi splined shafts

- Drum clutch for stopping ram at any position.

- All shafts are carried on ball bearings.

- Hand operated automatic pump for lubrication.

- Indirect indexing by dividing attachment.

- Variable automatic table feeds in all directions is optional.

INSPECTION : EACH MACHINE IS THOROUGHLY INSPECTED FOLLOWED BY TESTS CONFIRMED TO I.S.I. STANDARD.

Feeds, Speeds, Specifications (such as Travels) can be altered against demand but at an extra cost.

Accessories shown in catalogue/website are not part of standard accessories.

Note : In accordance with our continues improvements we reserve the right to change the design and specifications without any notice.

A slotting machine is a vertical reciprocating machine tool used to cut slots, grooves, and keyways in metal or other solid materials. It works similarly to a shaper machine, but instead of a horizontal motion, the tool moves vertically up and down.

United Machinery & Tools Corporation is a leading high quality slotting machines manufacturers and exporters in India, Punjab, Ludhiana, serving clients across the globe with precision engineering solutions. our company has built a strong reputation for delivering reliable, efficient, and technologically advanced slotting machinery tailored to meet the diverse needs of our clientele.

Our state-of-the-art Indian slotting machine manufacturing facility is equipped with the latest machinery and tools, ensuring high precision and consistency. With a skilled workforce and dedicated R&D team, we continuously improve our technology and product offerings.

For any Query, Contact Our Team