Power Presses

United Machinery & Tools Corporation

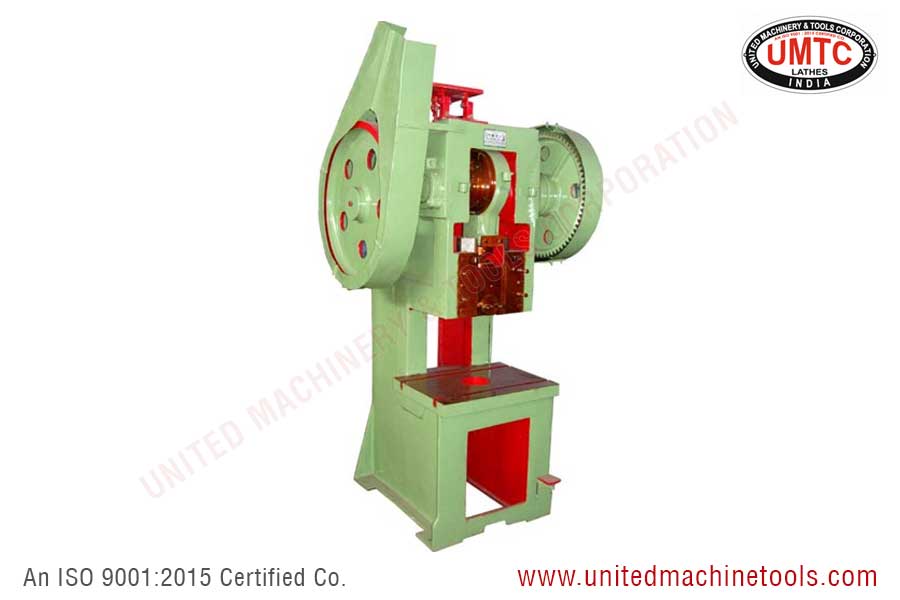

Power Press / Inclinable Type Power Press Machines

| TECHNICAL SPECIFICATION ( in mm ) - INCLINABLE TYPE TYPE POWER PRESS | ||||||||

| Capacity in Tons | 5 Tons | 10 Tons | 20 Tons | 30 Tons | 50 Tons | 75 Tons | 100 Tons | 150 Tons |

| Bed Size | 280x355 | 310x435 | 355x565 | 410x615 | 510x820 | 565x820 | 640x910 | 720x970 |

| Bed to Ram | 180 | 230 | 270 | 310 | 335 | 385 | 455 | 565 |

| Bolster Thickness | 58 | 58 | 63 | 63 | 70 | 78 | 83 | 90 |

| Crank Shaft Dia | 65 | 75 | 85 | 100 | 120 | 135 | 170 | 185 |

| Stroke Length | 45 | 52 | 63 | 83 | 95 | 110 | 115 | 127 |

| Gear Dia | 355 | 455 | 615 | 660 | 765 | 910 | 1020 | 1070 |

| Fly Wheel Dia | 460 | 535 | 561 | 675 | 765 | 840 | 910 | 1065 |

| Hole in Ram for Clamping Die | 25 | 25 | 28 | 32 | 39 | 45 | 52 | 58 |

| Floor to Top of Bed | 615 | 535 | 648 | 724 | 737 | 749 | 762 | 765 |

| No. of Strokes in Minute | 65 | 65 | 60 | 55 | 45 | 40 | 35 | 30 |

| Motor RPM | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 |

| Motor Power Required in HP | 1 | 1 | 2 | 3 | 3 | 5 | 7.5 | 10 |

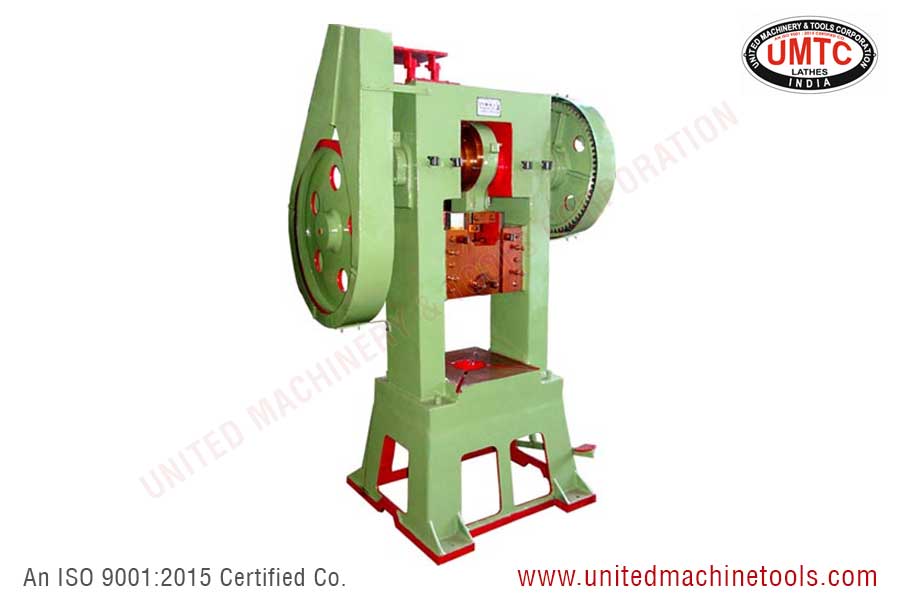

Pillar Type Power Press

| TECHNICAL SPECIFICATION (in mm) - PILLAR TYPE POWER PRESS | ||||||||||

| Capacity in Tons | 10 Tons | 20 Tons | 30 Tons | 50 Tons | 75 Tons | 100 Tons | 150 Tons | 200 Tons | 250 Tons | 300 Tons |

| Bed Size | 306x355 | 355x410 | 410x510 | 460x510 | 522x575 | 586x640 | 640x690 | 765x820 | 865x920 | 950x1050 |

| Bed to Ram | 230 | 255 | 295 | 330 | 382 | 435 | 460 | 510 | 612 | 625 |

| Bolster Thickness | 57 | 57 | 63 | 70 | 78 | 83 | 90 | 102 | 108 | 112 |

| Crank Shaft Dia | 75 | 85 | 100 | 120 | 135 | 170 | 185 | 204 | 230 | 250 |

| Stroke Length | 52 | 63 | 83 | 95 | 110 | 115 | 127 | 140 | 152 | 150 |

| Gear Dia | 458 | 560 | 615 | 665 | 765 | 910 | 1020 | 1225 | 1275 | 1350 |

| Fly Wheel Dia | 535 | 665 | 765 | 841 | 920 | 1070 | 1148 | 1275 | 1326 | 1500 |

| Hole in Ram for Clamping Die | 25 | 28 | 32 | 38 | 45 | 51 | 56 | 56 | 63 | 63 |

| Floor to Top of Bed | 625 | 625 | 652 | 652 | 663 | 663 | 690 | 715 | 715 | 800 |

| No. of Strokes in Minute | 65 | 60 | 55 | 45 | 40 | 35 | 30 | 30 | 30 | 30 |

| Motor RPM | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 |

| Motor Power Required in HP | 1 | 2 | 3 | 3 | 5 | 7.5 | 10 | 15 | 20 | 25 |

| FRAME : |

| Made of steel body with high grade quality, properly seasoned, after rough machining. Bearing surfaces are hand scraped. |

| CRANK SHAFT : |

| Made of special steel stock, to with stand the effective load, properly machined, ground all over, fitted in bushes with high accuracy. |

| FLY WHEEL : |

| Made of high grade cast iron and is designed to generate the required energy. |

| BRAKE : |

| The brake is powerful and works on the top dead centre and compensated by springs. |

| RAM SLIDE : |

| Made of cast iron with high grade quality, properly seasoned, after rough machining. Bearing surface are hand scraped, with reamed hole for die clamping. |

| STROKE : |

| Presses are manufactured with adjustable stroke and adjustable can be made by means of a worm. |

| ROLLING KEY : |

| The key is "double key rolling type" made out of special alloy steel EN series. |

| CLUTCH : |

| The clutch is very rigid, better supported, and less liable to suffer damage under heavy operating condition. The Clutch gives continuous stroke for mass production. |

| EJECTOR & DOUBLE KEY SYSTEM : |

| These are provided specially for the use of springs dies on special order. |

| LUBRICATION : |

| An efficient lubrication system has been provided to lubricate the sliding surfaces and moving parts. |

| DRIVE : |

| Presses are usually manufactured motorised but "Belt driven" presses can be supplied by on special orders. |

| NOTE : |

| (1) The motorised

presses are without motor but only the motor - attachment will be

supplied with them. (2) As the machines & Accessories are constantly being improved, we reserve the right to change the design & specifications. |

A Power Press Machine is a mechanical device used to cut, bend, shape, Stamping, Punching, Shearing & Bending or compress metal or other materials using pressure. It operates through mechanical or hydraulic power and is widely used in manufacturing industries for mass production of components.

United Machinery & Tools Corporation is a leading high quality Power Press Machines manufacturers and exporters in India, Punjab, Ludhiana, serving clients across the globe with precision engineering solutions. our company has built a strong reputation for delivering reliable, efficient, and technologically advanced Power Press machinery tailored to meet the diverse needs of our clientele.

Our state-of-the-art Indian Power Press Machine manufacturing facility is equipped with the latest machinery and tools, ensuring high precision and consistency. With a skilled workforce and dedicated R&D team, we continuously improve our technology and product offerings.

For any Query, Contact Our Team