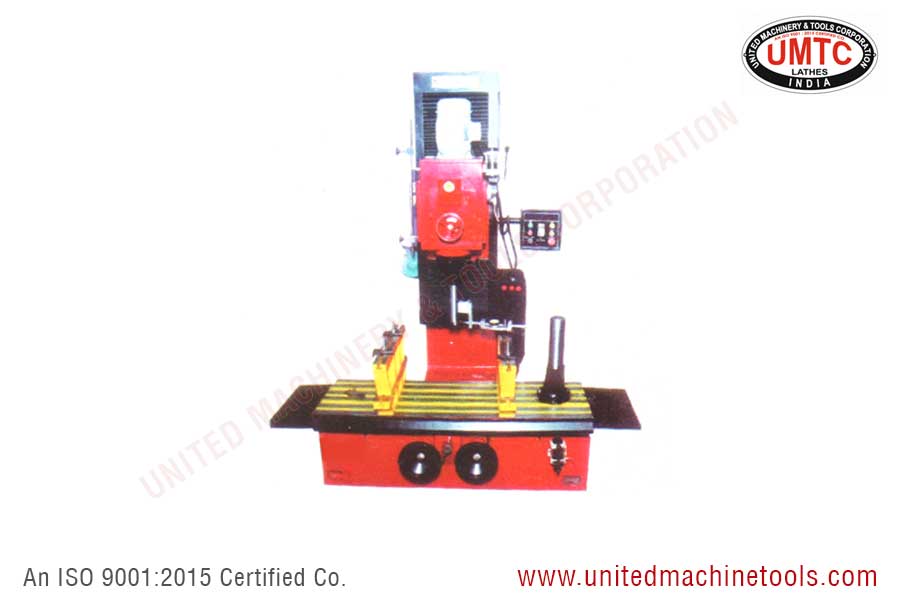

Vertical Boring Machine

United Machinery & Tools Corporation

Vertical Boring Machine

| MODEL | UNITED-600 W98 |

| Boring Capacity | 38-200 mm, 1.500" - 10" |

| Boring Depth Max. | 400 mm, 15.750" |

| Spindle Travel Max. (D) | 600 mm 23.625" |

| CI to Column ways | 254 mm, 10" |

| Useful Table Surface | 1500 x 457 mm, 60" x 18" |

| Table Cross Transverse Max. | 50 mm, 2" |

| Table Transverse Max. | 1500 mm, 60" |

| Spindle RPM-AC Drive | 50 to 600 |

| Feed Revolution | 0.07, 0.05, 0.10 |

| Motor Req. (Rapid up & Down) | 0.75 Kw, 1 H.P. |

| Motor Req. Spindle | 1.5 Kw, 2 H.P. |

| Net Weight (Approx.) | 3200 kg. |

Note : In accordance with our continues improvements we reserve the right to change the design and specifications without any notice.

A Vertical Boring Machine (VBM), also known as a Vertical Borer, is a machine tool used for boring large, heavy, and cylindrical components i.e Boring large holes in heavy components like engine blocks, turbine casings, and machine bases, Facing flat surfaces on the top of cylindrical parts, Turning and grooving operations on vertical surfaces, Ideal for heavy-duty and high-precision machining tasks in a vertical position. It is designed to machine internal surfaces such as holes, bores, and cylindrical recesses in large and heavy workpieces that are difficult to handle on horizontal machines.

United Machinery & Tools Corporation is a leading high quality Vertical Boring Machines manufacturers and exporters in India, Punjab, Ludhiana, serving clients across the globe with precision engineering solutions. our company has built a strong reputation for delivering reliable, efficient, and technologically advanced Vertical Boring machinery tailored to meet the diverse needs of our clientele.

Our state-of-the-art Indian Vertical Boring Machine manufacturing company facility is equipped with the latest machinery and tools, ensuring high precision and consistency. With a skilled workforce and dedicated R&D team, we continuously improve our technology and product offerings.

For any Query, Contact Our Team